At TPA Housing, we operate two integrated manufacturing facilities spanning 30,000 m², fully equipped to support the entire steel structure production process in-house. Our plants feature automated production lines and dozens of precision machines, including H-beam assembly units, submerged arc welding systems, and advanced powder coating equipment. Our production workshops including cutting, welding, assembly, and painting, are staffed with experienced quality control specialists who ensure every detail meets the highest standards. With an annual capacity of over 20,000 tons of steel structures, we’re committed to delivering on time and with consistent quality every time.

The CNC cutting workshop covers over 1,500 m² and is equipped with multiple high-performance CNC plasma and flame cutting machines. The facility includes gantry-style cutting platforms, bevel cutting equipment, and an automated nesting system, enabling highly efficient and precise operations. With an annual processing capacity of over 10,000 tons of steel plates, the workshop handles a wide range of materials, including steel plates, H-beams, and angle steel. We achieve cutting thicknesses of up to 100 mm with a precision tolerance of ±1 mm, ensuring accuracy and consistency for every project.

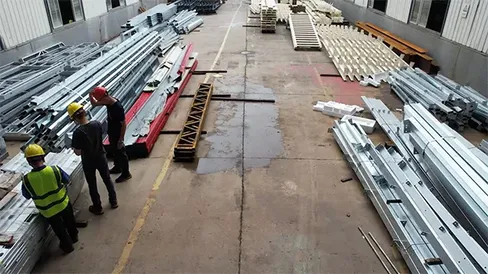

Spanning approximately 2,000 m², our assembly workshop is equipped with multiple advanced automatic welding systems, CNC-compatible cutting tools, and large-scale assembly platforms. With a total processing capacity of up to 8,000 tons per year, this facility supports the accurate assembly and prefabrication of a wide variety of steel components, including steel beams, columns, trusses, and custom-shaped structures. Multiple production lines ensure efficiency and flexibility, allowing us to meet the specific requirements of your project with precision and speed.

The submerged arc welding workshop covers approximately 1,800 m² and features a full suite of advanced equipment, including automatic submerged arc welding machines, semi-automatic welders, and smart welding control systems. With an annual capacity exceeding 7,000 tons, this workshop focuses on high-quality welding for a broad range of steel components, such as H-beams, steel girders, trusses, and large customized structures, ensuring strength, consistency, and lasting durability in every weld.

After shot blasting to Sa 2.5 grade, we offer the following protective coating systems:

The spray coating workshop occupies approximately 1,500 m² and features advanced automated spray lines and multi-functional paint booths, with an annual capacity of up to 6,000 tons. We use environmentally friendly and efficient equipment to apply primer, intermediate, and topcoat finishes across a wide range of steel structure components, ensuring even coverage, strong adhesion, and superior resistance to corrosion and weathering.

For projects where steel structures are exposed to humid climates, salt spray, or industrial pollutants, and where 50+ years of maintenance-free corrosion protection is essential, hot-dip galvanizing is the recommended solution. The standard zinc coating thickness is 80 microns, and it can be customized based on your specific requirements.

Speak to our engineers.