- Home

- Steel Structure Solutions

- Prefabricated Houses

Custom Prefabricated Construction

From conception to completion

Prefabricated house refers to a building method where components are manufactured in a factory and then transported to the site for quick assembly. Our prefabricated houses adopt a modular design concept, enabling industrialized construction through standardized production, precise fabrication, and assembly-based installation. Compared to traditional cast-in-place buildings, our prefab structures can achieve a prefabrication rate of over 85% and shorten the on-site construction period by 60%, making them a key development direction for the modern construction industry.

Do you dream of a beautiful, durable, eco-friendly, and cost-effective home? Our light steel villas are built with aerospace-grade galvalume steel, offering seismic resistance up to magnitude 7 and wind resistance up to level 9.

Looking for a safe, modern, and cost-effective multi-storey solution? Our multi-storey steel buildings use military-grade steel with seismic resistance up to magnitude 8 and wind resistance up to Level 15.

Sandwich panel prefabricated houses consist of prefabricated components produced in factories and assembled on-site, significantly reducing the construction timeline.

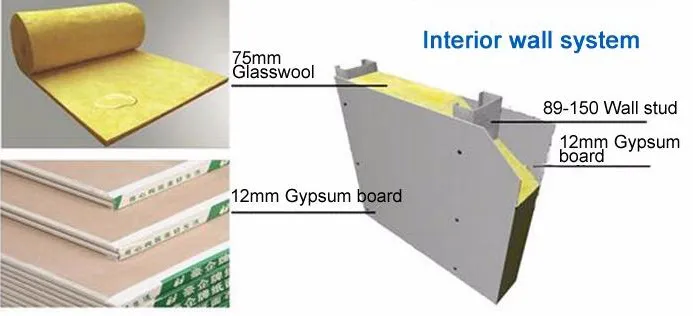

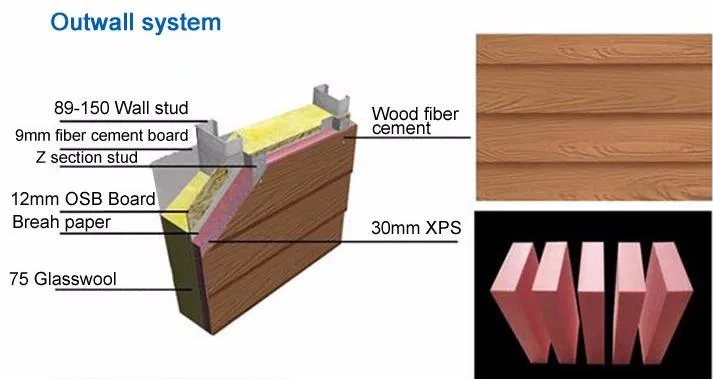

Our prefabricated houses are built using the following core systems:

H Section

H Section I Section

I Section Square tube

Square tube Circular tube

Circular tube Floor decking steel sheet

Floor decking steel sheet C Section

C Section Z Section

Z Section Angle iron

Angle iron

Prefabricated houses are typically built using pre-engineered steel components. These materials are often treated with protective coatings or galvanized to prevent rust and corrosion.

With proper maintenance, a prefabricated house can last 40–50 years or more. The actual lifespan depends on factors such as construction quality, environment, and the frequency and quality of upkeep.

The process usually involves site preparation, architectural design, factory production, logistics and transportation, and on-site installation. Completion time varies depending on the building’s size, complexity, and local weather conditions.

Yes. During the design phase, we consider local building codes, insulation standards, and environmental factors. Customers should provide these requirements at the inquiry stage to ensure compliance and customization.

Yes. Modular design allows disassembly and relocation. Upon reassembly, repainting and resealing may be needed. If any components are damaged, they can be easily replaced due to the standardized modular structure.