Insulated Roof Sandwich Panel

Sandwich Roof Panel System

Insulated roof sandwich panels, widely used roofing systems for steel structure buildings, are commonly designed with a tongue-and-groove edge profile, where one side forms a groove and the other a tongue. Once assembled, the panels interlock tightly, helping reduce the risk of water penetration along roof joints.

Panels can be fixed using exposed fasteners or concealed fixing systems, improving overall roof integrity, preventing panel uplift, and enhancing wind resistance. This roofing system has been extensively applied in industrial plants and large steel structure buildings, offering a good balance between installation efficiency and long-term performance.

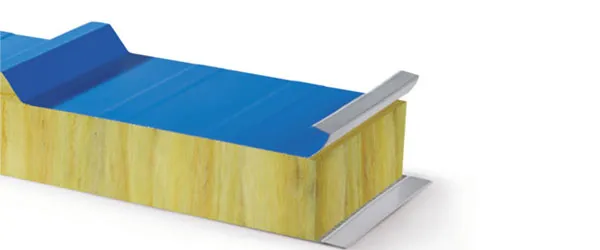

Glass Wool Sandwich Panels

Glass wool, made from glass fibers, is an inorganic insulation material known for its low density and stable performance. It provides effective thermal insulation, sound absorption, and corrosion resistance, with a low thermal conductivity. Thanks to its lightweight nature, glass wool helps reduce roof structural loads. It is commonly used in industrial workshops, warehouses, and projects where noise control is an important consideration.

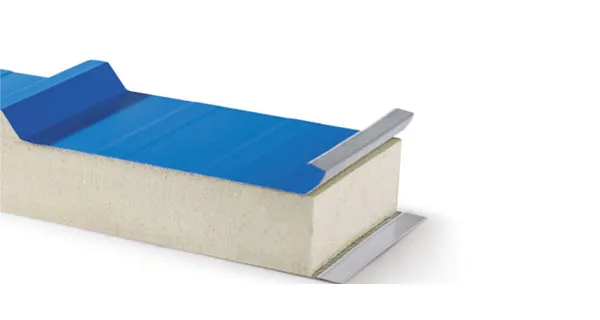

PU Sandwich Panels

Polyurethane (PU) is an elastic material positioned between plastic and rubber, offering a combination of mechanical strength and flexibility that conventional plastics or rubber materials cannot provide. PU sandwich panels feature strong abrasion resistance, chemical resistance, high tensile strength, elasticity, and load-bearing capacity. They also perform well under high pressure and provide vibration damping and impact absorption. With a wide hardness range, PU panels are suitable for roofing applications requiring higher structural strength and long-term durability.

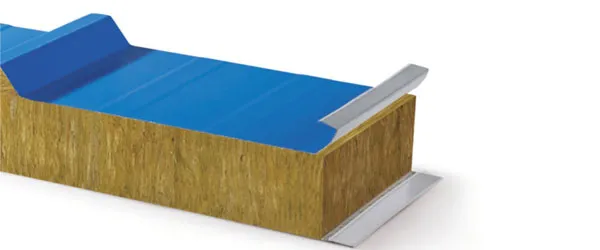

Rock Wool Sandwich Panels

Rock wool, also known as mineral wool, is produced from natural rock and mineral materials and formed into fine, fibrous insulation. It offers excellent fire resistance and sound insulation properties. Rock wool panels are widely used in steel structure buildings where higher fire-rating requirements apply, such as industrial facilities and large public buildings.

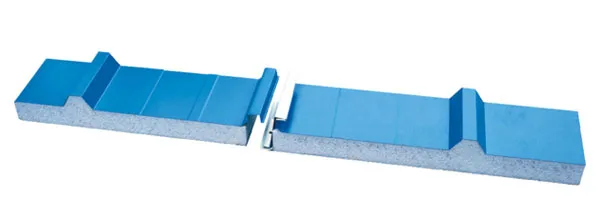

EPS Sandwich Panels

Expanded polystyrene (EPS) panels feature a closed-cell structure that provides effective thermal insulation. EPS insulation is widely used in building walls, roofing systems, composite panels, cold storage facilities, air-conditioning insulation, vehicles, ships, underfloor heating systems, and decorative applications. EPS roof panels are valued for their versatility, lightweight structure, and cost efficiency across a broad range of construction scenarios.

Nip Type Joint

The nip-type joint system forms a continuous roofing surface through tight interlocking between panels. This design significantly reduces the number of exposed fasteners, lowering the risk of water ingress while enhancing the overall visual appearance of the roof.